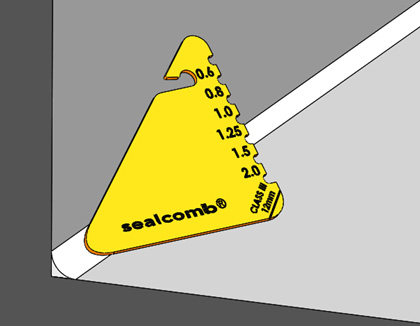

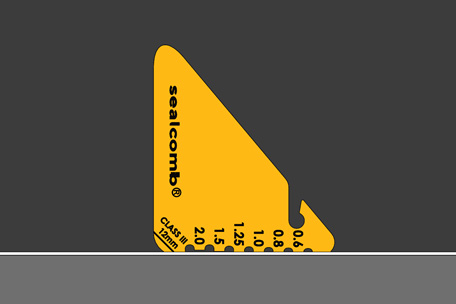

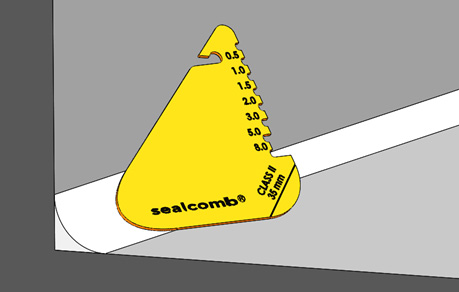

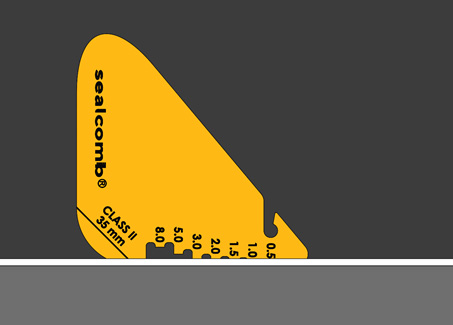

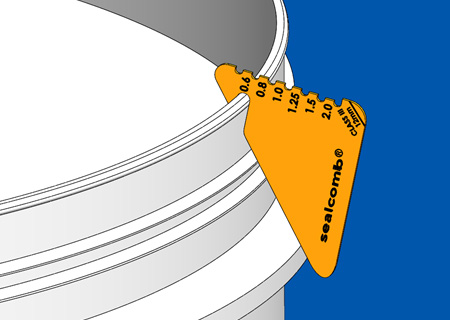

Press the Wet Film gauge component into wet coating. Withdraw upward and identify the deepest tooth having membrane coated on it and the next highest tooth that does not have membrane coated on it. The exact wet film thickness will lie between these two readings. Clean the tool after each use.

STEP 6 (During membrane installation) Dip the sealcomb wet film gauge into the freshly applied liquid membrane to measure the wet film thickness of the liquid membrane.